|

|

‘OXYTEA’ CONTINUOUS

FERMENTING MACHINES

THE

IDEAL

FERMENTING SOLUTION

|

|

FERMENTATION - THE BASICS |

|

Fermentation is the

process during which the polyphenols in the tea leaf are

oxidized in presence of enzymes and subsequently condensed to

form colored compounds contributing to the quality attributes

of tea. Fermentation starts immediately after cell rupture

during rolling and is continued in the next stage. Optimum

temperature for fermentation is 24 to 29 degrees Centigrade

and optimum hygrometric difference is 1 to 1.5 . During

fermentation, the leaf changes colour into a dark copper tone.

Here, typical aroma develops. When fermentation is judged to

be sufficient, the leaves must be dried immediately to stop

further fermentation. Traditionally, optimum fermentation is

reached after forty five minutes to three hours.

|

|

'OXYTEA' - THE RANGE |

|

The 'OXYTEA'

Range of Continuous Fermenting Machines epitomizes Aarkay's

maiden effort to offer the ideal fermenting solution to the

Tea Industry at an affordable price. The 'OXYTEA' has a

simple modular architecture designed to provide the hygienic,

hassle - free, labour - saving answer to the Tea Industry's

need for a modern, effective and space - saving Fermenting

solution. The 'OXYTEA' is available in two basic models -

the 'OXYTEA' - SST and the 'OXYTEA' - PVB. As indicated by

the nomenclature, the SST model utilizes Stainless Steel

Trays for making up the moving bed on which the leaf is

fermented. The PVB model, on the other hand, uses imported PES

- grade nylon woven fabric belt with 45% open area. Although

the standard 'OXYTEA' design is a 6 ft. wide, single deck,

modular structure, to suit the individual needs of the

discerning customer, the 'OXYTEA' may be offered in an 8 ft.

wide structure or a two or three tier architecture which

reduces the machine length considerably.

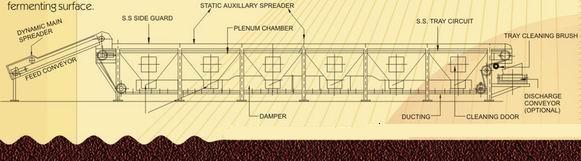

OXYTEA - SIDE SECTIONAL VIEW

|

|

'OXYTEA' - SST |

|

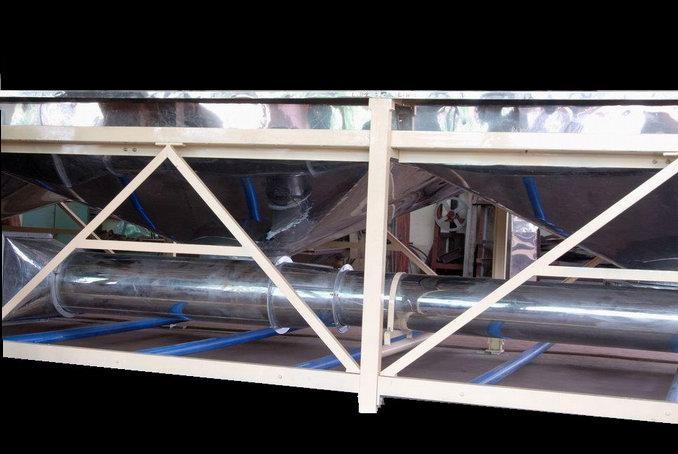

The

OXYTEA-SST

uses sturdy, six feet long perforated stainless steel trays

which allow the humidified air to penetrate through the leaf

for even and optimum fermentation. Individual trays can be

replaced as/when necessary with minimum downtime unlike belt

type fermenting machines, which require expensive maintenance

and much longer replacement/down time. It may also be noted

that Stainless steel has a high thermal conductivity, which is

a vital and necessary characteristic of the ideal fermenting

surface.

|

|

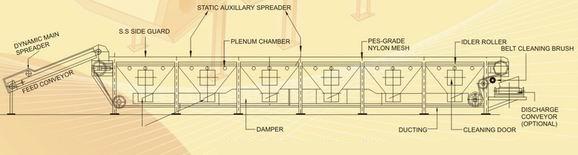

'OXYTEA' - PVB |

|

The

OXYTEA-PVB

uses imported PES – grade nylon woven fabric belt with 45%

open area. The PES – grade Nylon mesh guarantees better and

consistence performance as the material (PES or Polyether

Sulfone) is an amorphous engineering thermoplastic plastic

with good high temperature resistance.

It

has excellent resistance to hydrolysis and repeated

sterilization. Its outstanding rigidity and

mechanical properties

are little affected even at a continuous use temperature of

about 185 C. Basic PES characteristics include Very high

rigidity, good dielectric properties, high mechanical

strength, good dimensional stability, good resistance to

hydrolysis and sterilization, good oxidative stability, and

inherent flame retardance. The greater open area (almost

three-quarters more open area than SS tray/belt CFMs) ensures

even fermentation across the tea bed and improves the overall

process quality.

|

|

'OXYTEA' FEATURES |

|

DESIGN & CONSTRUCTION

A

robust and sturdy construction with every emphasis on quality

in both machine design as well as the material of construction

ensures a trouble - free operating environment and a longer

life cycle with minimum downtime and practically zero

maintenance costs. The low height construction allows easier

daily supervision, cleanliness and maintenance.

|

|

HIGH OUTPUT & MODULAR CONSTRUCTION

The

'OXYTEA' is a modular machine with flexibility in design and

construction, thereby enabling the end user to choose a

customized machine as per the capacity requirements.

Individual machine outputs range from 1000 to 2000 kgs. of

withered leaf per hour.

|

|

CENTRALIZED CONTROL PANEL

A

composite centralized console is provided for easier and

smoother control and single-point machine operation.

|

|

DRIVE SYSTEM

A

mechanical variable speed drive facilitates wide variation in

fermenting time from 30 mins to 150 mins.

|

|

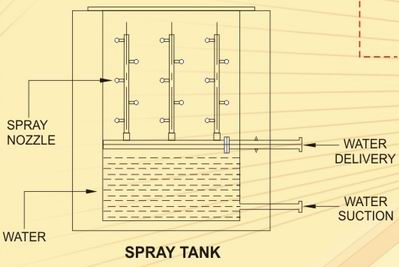

HUMIDIFICATION & DISTRIBUTION SYSTEM

An

indigenously designed Humidification Chamber ensures

continuous supply of fresh humid air at high RH to the tea bed

without allowing water droplets to enter the machine.

A dynamically balanced centrifugal blower supplies the

humidified air from the Humidification chamber to the air duct

through an overhead or ground ducting system.

An

aerodynamically designed Stainless Steel plenum chamber with

air duct facilities even distribution of air throughout the

effective area of the machine for even and perfect

fermentation.

|

|

SPREADER SYSTEM

A highly effective spreader system comprising of a

dynamic main spreader and a static auxiliary spreader ensures

even fermentation throughout the cross-section of the tea bed.

|

|

CLEANING BRUSH

A self-cleaning and easily removable high speed

brush cleans the belt in motion after the tea is discharged.

|

|

FEED CONVEYOR

A full-width feed conveyor with synchronized speed

arrangement ensures uniform feed across the entire width of

the machine.

|

|

A VERSATILE MACHINE

The

'OXYTEA' is equally suitable for both CTC as well as

Orthodox Teas.

|

|

|

|

TECHNICAL

SPECIFICATIONS

& DATA |

|

OVERALL

DIMENSIONS |

|

'OXYTEA' MODEL |

M6.7 |

M6.8 |

M8.7 |

|

Length |

16 mtrs. |

18 mtrs. |

20 mtrs. |

|

Width (incl. Drive Unit) |

2.770 mtrs. |

2.770 mtrs. |

3.270 mtrs. |

|

Width (excl. Drive Unit) |

2.125 mtrs. |

2.125 mtrs. |

2.625 mtrs. |

|

Height

|

1.315 mtrs. |

1.315 mtrs. |

1.315 mtrs. |

|

|

|

HORSE POWER

(INSTALLED) |

|

'OXYTEA' MODEL |

M6.7 |

M6.8 |

M8.7 |

|

Main Drive |

3 HP |

3 HP |

5 HP |

|

Feeder/Up-turner |

2 HP |

2 HP |

2 HP |

|

Cleaning Brush |

1 HP |

1 HP |

1 HP |

|

Fan |

5 HP |

5 HP |

7.5 HP |

|

Humidifier / Pump |

2 HP |

2 HP |

2 HP |

|

TOTAL* |

13 HP (9.7 KW) |

13 HP (9.7 KW) |

17.5 HP (13.0 KW) |

|

|

|

|

|

|

CAPACITY |

|

'OXYTEA' MODEL |

M6.7 |

M6.8 |

M8.7 |

|

Capacity in Withered leaf per hour at 3"

to 3.5" thick spread and 55 - 60 mins. residence time. |

850 - 950 |

1000 - 1100 |

1200 - 1400 |

|

|

* Please note that a 2HP

pump has been provided for long-term durability and better

humidification. Furthermore, 1 HP extra will be required in

case of Motorised Plough. |