|

|

|

|

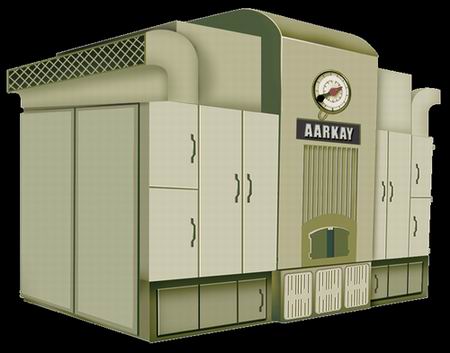

‘SUPER’

HEATERS

THE WORLD’S MOST EFFICIENT

SOLID FUEL BASED INDIRECT FIRED HEATERS FOR THE TEA INDUSTRY

|

|

Introduced to the

Tea Industry in the mid-eighties and subsequently evolved into

the revolutionary Phase – II design at the beginning of the

new millennium, the ‘SUPER’ heater remains AARKAY’s

biggest contribution to the Industry at large. In an industry

plagued with high manufacturing costs, the ‘SUPER’ heater

guarantees coal ratios as low as 0.4 per kg. of made tea. With

close to 150 installations in

North India

alone, the ‘SUPER’ has found industry - wide acceptance

with both the corporate sector as well as the private bought

leaf / plantation sector.

The

SUPER heaters can be fired with either coal - lump

or dust, leco, firewood, gas or oil. They come with AARKAY’s

hassle-free COMPOSITE GUARANTEE and SINGLE POINT SERVICE since

AARKAY is also a leading manufacturer of Chain Grate Stokers

with more than 200 installations.

|

|

THE 'SUPER' CONCEPT |

|

It

was in the mid-eighties that Aarkay launched its range of

‘SUPER’ – Phase I heaters, coining the term ‘PASS’

in the process. The SUPER heaters sought to seek a balance

between the flow of the process air and the path of the flue

gas within the heater. The 4 - stack Tube Bank structure of

the fourth-Generation ‘Special’ Heaters was retained. A

unique cross- path was evolved for the flow of process air.

The

SIX

PASS

was

coined to denote this new flow-design of process air. Coupled

with automated coal stoking (Aarkay remains, to date, the only

heater manufacturer to offer the complete single-point heating

solution with automated stoking), the result was phenomenal

– a range of super-efficient heaters which could take upon

any Dryer, Conventional or Fluidized, and was capable of

giving unheard-of fuel economies. The chimney temperature was

brought down much below the targeted 115 degree mark and the

Dryer Inlet Temperature would remain rock-steady in any

climatic conditions.

Continuous

on-site R&D and the undying commitment to pioneering and

excellence finally led to the evolution of the Phase – II

design, a revolutionary new heating system for the new

Millennium. The Phase –II design has a unique 6-stack

structure. The robust simplicity of the Phase – I design has

been retained. The flow of the process air has been

re-designed to include initial passage through the new

in-built heat recovery unit which recycles the spent heat from

the exiting flue gas before discharging it through the

chimney. The Phase –II design employs a staggering figure of

nearly 400 tubes of different shapes, sizes and design.

It

may be noted here that the ‘SUPER’ theory does not

advocate the replacement of C.I. tube stacks with fabricated

M.S. tubes in the main heater body as the rough-surfaced oval

CI Tubes promise better heat absorption and a much higher life

span as compared to their smoothened round fabricated

counterparts.

|

|

TECHNICAL

SPECIFICATIONS |

|

MODEL |

10 |

12 |

14 |

16 |

18 |

|

|

Phase-I |

Phase-I |

Phase-I |

Phase-II |

Phase-I |

Phase-II |

Phase-I |

Phase-II |

|

Hot Air Output Capacity (Kgs./hr. at 140º C) |

9,000 |

14,000 |

22,000 to 24,000 |

32,000 to 33,000 |

38,000 to 39,000 |

|

Heat Generation Capacity (K. Cal./hr. at 5000 K. Cal / kg. of coal) |

4,00,000 |

6,00,000 |

7,00,000 to 8,00,000 |

9,00,000 to 10,00,000 |

11,50,000 to 12,50,000 |

|

Fuel Consumption (per hour)

|

|

|

Lump / Dust

Coal (kgs.)

|

60-70 |

80-100 |

100-120 |

85-100 |

130-150 |

110-130 |

190-210 |

160-180 |

|

Leco (kgs.)

|

45-55 |

60-70 |

75-85 |

65-70 |

100-110 |

85-95 |

140-150 |

120-130 |

|

Fire

Wood (m3) |

0.3 |

0.4 |

0.6 |

0.5 |

0.75 |

0.7 |

1.0 |

0.9 |

|

|

|

'SUPER' FEATURES |

|

VERSATILE

The SUPER

comes in varying sizes to suit various Dryer capacities and can be fired with either coal, leco, firewood, gas or oil.

|

|

FUEL ECONOMY & HEAT TRANSFER

The SUPER

Phase – I (

SIX

PASS

) and Phase- II (

EIGHT

PASS

) models optimize the heat

transfer process between the flue gas and the process air and

thereby offer unprecedented fuel economies as low as 0.4 –

0.5 kg. of coal / kg. of made tea.

|

|

BETTER HEAT RETENTION & ROCK STEADY

DRYER INLET TEMPERATURE

The

‘SUPER’ design optimizes heat retention inside the heater

and reduces heat loss. The Dryer Inlet temperatures remain

rock-steady even in the most adverse climatic conditions.

|

|

CASTING LIFE & MAINTENANCE

All Cast

Iron parts are made from superior quality Graded Castings for

better durability and heat resistance. As there are no moving

parts, very minimal maintenance is required on a regular basis

except for cleaning of tube banks. Provision of conveniently

placed Cleaning and Soot removal doors at the front and rear

ends facilitate easy tube cleaning, soot removal and casting

inspection.

|

|

EASY & QUICK INSTALLATION

‘SUPER’

Heaters can be erected on a firm and rigid 9” thick concrete

base set on solid Earth. No excavation and no foundation bolts

are required.

|

|

INDUCED DRAFT SYSTEM

The

‘SUPER’ heaters are designed to handle both Induced and

Forced Air. ‘SUPER’ Induced Draft fans operate on

relatively low RPM, thereby enhancing impeller life and

reducing risk of back-pressure. Inlet and bypass dampers are

provided in the fan for better control.

|

|

TUBE BANK STACKS

All

the Tube Bank Stacks in the Main heater body are made from

Cast Iron. The single-cast CI Tube Bank with rough-surfaced

oval CI Tubes promise better heat absorption and a much higher

life span as compared to its fabricated MS counterpart with

smoothened round tubes.

|

|

HEAT RECOVERY SYSTEM

‘SUPER’

Phase-II Heaters are fitted with unique built-in Heat Recovery

Units that pre-heat the process air with recycled waste heat

with the result of giving unprecedented and unmatched fuel

economies.

|

|

MECHANICAL STOKING & A COMPOSITE

GUARANTEE

Aarkay remains, to-date, the only heater manufacturer

to offer a complete heating system with built-in mechanical

stoking capability. Hence,

our composite guarantee also covers the entire heating system

in toto without the room for any conflict or controversy as

regards the quality and performance of the ‘SUPER’ heating

system.

|

|

|