|

|

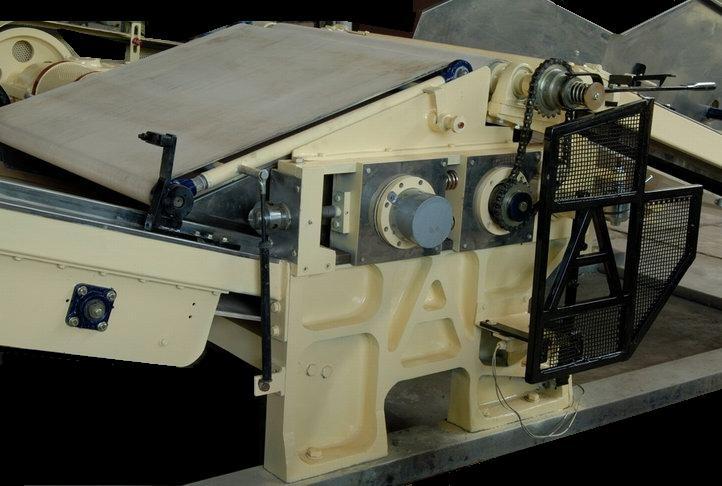

‘ULTIMA’

CTC MACHINES

THE

'ULTIMATE' CTC MACHINE

Launched in the new millennium after years of R&D, the

'ULTIMA' epitomizes Aarkay's commitment to balance quality and

cost. A vibration - free and sturdy construction, modular

design, cooler cuts, higher percentage of Brokens, longer life

of bearings, reduced power consumption, and a spillage - free

performance is what makes the 'ULTIMA' truly the numero uno in

its class.

Available in

various models from 24" to 52" in width and

8.5" to 13" in roller diameter, the ULTIMA has a

versatile design to suit the various needs of the discerning

consumer. The 'ULTIMA' is also the first and only CTC machine

in the world to be available in both Straight Pedestal and

Inclined Pedestal versions with a standard/uniform machine and

component structure.

|

|

'ULTIMA' FEATURES |

|

HEAVY & ROBUST CONSTRUCTION

The

'ULTIMA' employs superior Alloy Grade castings for pedestals,

duly re-inforced, for higher rigidity and vibration - free

performance.

|

|

LOW HEIGHT

The

low height of the 'ULTIMA' allows for easier and better

supervision. Roller changing has become faster and easier,

leading to ease in maintenance activities. The low height also

enables vibration - free and reliable performance.

|

|

INTERCHANGEABILITY

Computer

- Aided Design and precision

engineering enables interchangeability of H.S. and S.S.

rollers as well as any parts between the different cuts.

|

|

CASTING LIFE & MAINTENANCE

All Cast

Iron parts are made from superior quality Graded Castings for

better durability and heat resistance. As there are no moving

parts, very minimal maintenance is required on a regular basis

except for cleaning of tube banks. Provision of conveniently

placed Cleaning and Soot removal doors at the front and rear

ends facilitate easy tube cleaning, soot removal and casting

inspection.

|

|

BEARING HOUSING & ROLLER CHANGING

The

'ULTIMA' incorporates a unique Spring Loaded Housing System

that nearly doubles the life of the bearings while ensuring

uniform cutting of the tea leaves by acting as a 'shock

absorber' for the bearings and allowing for automatic

correction in case of bearing wear. As a standard option, the

regular Cartridge type Bearing Housing may be employed.

Hardened

bearing sleeves have been provided in the 'ULTIMA' as a

standard feature for faster and smoother roller

changing.

|

|

HYDRAULIC 'CONTINUOUS' MOVING COVERS

The

hydraulic mechanism introduced in the 'ULTIMA' for lifting the

moving covers allows for easier access to the belly of the

cutting units for regular cleaning which is essential to avoid

bacterial contamination. The Moving covers have continuous

free movement, unlike the cumbersome ratchet and pawl design

of the older machines.

|

|

REDUCED POWER CONSUMPTION

Installed

power rating has been brought down by 5 HP per cut. A sturdy

machine design with heavy duty bearings, and incorporation of

auto-dejamming and auto-tripping as standard features have

enabled this reduction in both installed and actual power

consumption, leading to huge savings in the annual electricity

bill.

|

|

DRIVE

Positive

drive heavy duty Gear Box is fitted with hardened shafts,

gears and heavy duty bearings for longer life and easier

drive. Heavy duty propeller shafts are used for instant and

zero spillage propelling of rollers.

|

|

COOLER CUTS

Bigger

gaps between rollers and conveyor belts allow better air entry

in the cutting units. An efficient cooling system with a

dynamically balance centrifugal cooling fan and ducting

connections to each cuts has been provided for cooling the

teas.

|

|

HYGIENIC FEATURES

Moving

covers with hydraulic lifting systems, use of imported

food-grade PVC belts, and specially designed detachable

Stainless Steel side guards enhance machine hygiene by not

allowing tea accumulation in the inaccessible areas and

thereby effectively eliminating the bacterial menace.

Unlike

static covers where the cut 'mal' gets deposited on them and

thus make them the mother-bed of bacteria, the moving covers

with imported PVC belts do not allow any deposit or

accumulation of teas. There is also no lump or ball formation.

Based

on the experience that with 40" PVC belts, the full

cutting area of the 36" CTC Machine cannot be used and

that this causes side spillage, wider and non-sticky food

grade PVC belts are provided for hygienic and longer

life. Hence, in a 36" machine, 42" wide belts are

used.

|

|

AXIAL PITCH ADJUSTMENT

Matching

of HS and SS Rollers is vitally important. Axial pitch

adjustment has been made simpler for easy matching.

|

|

MICRO MESHING

Meshing

of rollers with micro-fine tuning of cutting has been

incorporated with simple and error-free adjustment. After

having adjusted microdial matching on both ends, just

synchronize Micro adjustment for cutting with the knob, which

is very easy to operate.

|

|

IMPROVED CLUTCH SYSTEM

A

simple and operator - friendly clutch system has been

introduced in the 'ULTIMA' for engaging and dis-engaging moving

of conveyor belts within a fraction of a second.

|

|

IMPROVED DEJAMMING AND AUTO - TRIPPING

An

improved de-jamming system and auto-tripping have been

incorporated in the 'ULTIMA' as standard features to protect

rollers and electrical motors and to achieve immediate

re-instatement and same matching / meshing.

|

|

LOW INCLINATION OF CONVEYOR BELTS

The

'ULTIMA' design incorporates a low 14 degree inclination of

conveyor belts. This prevents roll-back and tea deposition on

the sides, provides more gap for ambient air in-flow, and

allows for zero ball or lump formation.

|

|

ZERO SPILLAGE AND ZERO-TRACKING

The

specially designed SS side-guards, wider conveyor belts and

and the low inclination of the Conveyor Belts have all been

designed to make the 'ULTIMA' virtually a Zero Spillage

machine.

Special ribbed Zero-tracking Conveyor Belts with grooved

conveyor rollers have been employed to completely eradicate

the issues of belt-slippage and folding, thereby eliminating

wear and tear of the belts and guaranteeing zero side

spillage.

|

|

VALUE ADDITION IN INPUTS

The Machine Pedestals are the heaviest in the Tea Industry. All

the contact points with tea are made of AISI304 grade

Stainless Steel material only. The Dejamming Handle, Clutch

lever, Microdial, Micro - mesh arrangement, ratchet, etc. are

all either hard-chromed or made of Stainless Steel, precision

engineered and painted with long lasting paint with silken

finish. The aesthetic and refined looks of the 'ULTIMA' and its

eye-catching appearance is guaranteed to captivate your

senses. All electricals are outsourced from the world leaders

in the field such as Greaves and Siemens. This is one machine

where the word 'compromise' does not figure in the details or

the description.

|

|

TRULY FLEXIBLE AND MODULAR

The 'ULTIMA' is

the first and only CTC machine

in the world to be available in both Straight Pedestal and

Inclined Pedestal versions with a standard/uniform machine and

component structure. It may be purchased in

configurations of one to six cuts as per the nature of the tea

and the purpose of the operation. The Machine itself is

available in various sizes such as 24", 30"

36", 38" and 42" in the Standard (8.5")

and Medium (9.5") models, as well as 24", 30",

36", 38", 42", 48" and 52" in the

Jumbo (13") model.

|

|

|

|

TECHNICAL

SPECIFICATIONS

& DATA |

|

OVERALL

DIMENSION |

|

MODEL |

ULJ30 |

ULS/M 30 |

ULJ36 |

ULS/M 36 |

|

|

3 cut |

4 cut |

3 cut |

4 cut |

3 cut |

4 cut |

3 cut |

4 cut |

|

Length (mm) |

10481 |

13122 |

9908 |

12346 |

10481 |

13122 |

9908 |

12346 |

|

Width (mm) |

2245 |

2245 |

2245 |

2245 |

2400 |

2400 |

2400 |

2400 |

|

Height (mm)

|

1090 |

1090 |

1040 |

1040 |

1090 |

1090 |

1040 |

1040 |

|

Output (GL/hr) |

1000 - 1100 kgs. |

800 - 900 kgs. |

1100 - 1200 kgs. |

1000 - 1100 kgs. |

|

|

|

HORSE POWER

(RECOMMENDED) |

|

MODEL |

ULJ30 |

ULS/M 30 |

ULJ36 |

ULS/M 36 |

|

Normal |

20-15-15-15 |

15-15-15-15 |

25-20-20-20 |

20-15-15-15 |

|

Hard Cut |

25-20-20-20 |

20-15-15-15 |

30-25-25-25 |

25-20-20-20 |

|

|

|

CONVEYOR

BELT (IMPORTED) |

|

MODEL |

ULJ30 |

ULS/M 30 |

ULJ36 |

ULS/M 36 |

|

|

Width (mm) |

Length (mm) |

Width (mm) |

Length (mm) |

Width (mm) |

Length (mm) |

Width (mm) |

Length (mm) |

|

Feed |

900 |

4876 |

900 |

4876 |

1050 |

4876 |

1050 |

4876 |

|

Subsequent cut |

900 |

6096 |

900 |

5790 |

1050 |

6096 |

1050 |

5790 |

|

Moving Cover

|

900 |

2030 |

900 |

1830 |

1050 |

2030 |

1050 |

1830 |

|

|

|

ROLLER

SHARPENING DATA |

|

Roller |

Diameter |

Tilt Angle º |

Cutter Angle º |

Helical |

Chasing Profile |

|

13" |

8 T.P.I. |

45.6 |

65 |

80 |

55º / 45º |

|

|

10 T.P.I. |

45.6 |

65 |

96 - 100 |

55º / 45º |

|

9.5" |

8 T.P.I. |

52 |

65 |

60 |

55º / 45º |

|

|

10 T.P.I. |

52 |

65 |

70 |

55º / 45º |

|

8.5" |

8 T.P.I. |

47 |

70 |

50 |

55º / 45º |

|

|

10 T.P.I. |

47 |

70 |

60 |

55º / 45º |

|

|

|

SPEED |

|

MODEL |

ULJ (13") |

ULM (9.5") |

ULS (8.5") |

|

|

Motor RPM = 1500 |

Motor RPM = 1500 |

Motor RPM = 1500 |

|

H.S. Roller |

550 |

630 |

720 |

|

S.S. Roller |

55 |

63 |

72 |

|

Gear Box ratio |

10:1 |

10:1 |

10:1 |

|

NOTES:

Conveyor belt can be provided long or

short as per requirement and space availability. Discharge

belt length may vary as per requirement.

Recommendations given above are

subject to various factors such as leaf quality and type of

cuts. In view of commitment to continuous research,

development and product improvement, specifications may change

from time to time. |