|

INTRODUCTION - THE BASICS OF FLUIDIZED BED DRYING |

|

The Fermented

CTC Tea is spread evenly at the feed end of the

perforated plate which is fixed onto the plenum

chamber. The Plenum chamber vibrates while hot air is

passed from beneath the perforated plate, thereby

effectively fluidizing the tea which moves forward due

to the mechanical vibration imparted to the perforated

Grid plate. The drying is completed in a single pass

in a controlled environment where the drying

temperature and discharge time may be suitably varied.

The fibre and dust particles are picked up by the dust

extraction system and collected in the cyclone. The

saturated air is removed whereas the hot and dry air

is re-circulated for better thermal efficiency.

|

|

THE MEGAPUT – DESIGN

ELEMENTS |

|

A sturdy and

robust construction with aesthetic beauty

characterizes the MEGAPUT. Needless to say, all parts

in direct contact with moisture or wet air are made of

high grade, non-magnetic, non-corrosive Stainless

Steel material only. High-efficiency hot and cold air

blowers ensure maximum power efficiency. High grade

insulation throughout the drying system minimises heat

loss thereby inducing maximum thermal efficiency.

Computer Aided Design and practical R&D have been

employed to ensure adequate control and uniformity in

air distribution and consequently in tea drying,

thereby leading to superior output quality of made CTC

tea. A centralized Console with adequate

instrumentation and multi-point temperature display

allows for easy, single - point operation.

|

|

|

|

|

|

|

|

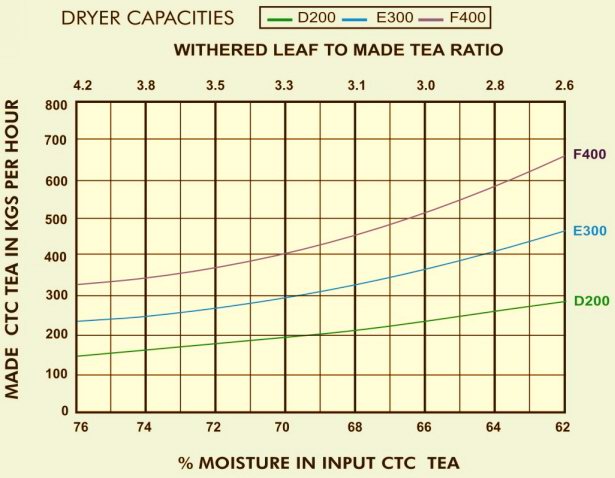

THE DRYING CURVE |

|

|

|

TECHNICAL SPECIFICATION |

|

MODEL |

MEGAPUT

D-200 |

MEGAPUT

E-300 |

MEGAPUT

F-400 |

|

Capacity in Kgs./hr. (Made CTC Tea) *

(Moisture content of leaf: 62 – 76 %, Inlet temp. :

130 +/- 5 degrees centigrade) |

175 to

300 |

250 to

500 |

360 to

750 |

|

Water Evaporation

Capacity (Kgs./hr.) |

400 |

650 |

1000 |

|

Size of Drying Chamber

(mm x mm) |

5775L x

1100W |

7850L x

1150W |

8400L x

1720W |

|

Max. Heat Load

requirement (Kcal./hr.) |

3,75,000 |

6,50,000 |

9,50,000 |

|

Installed

Power** |

|

|

|

|

A. Drying System |

16.4 kW

(22 HP) |

21.6 kW

(29 HP) |

32.5 kW

(43.5 HP) |

|

B. Dust Collection |

7.5 kW

(10 HP) |

13.5 kW

(18 HP) |

18.6 kW

(25 HP) |

|

Type of

Fuel |

---------------------- Coal,

Wood, Gas, Oil and Steam -------------------- |

|

Fuel

Consumption (per Kg. of

Made Tea) |

|

|

Direct Oil Fired |

------------------------------- 0.18 to

0.22 Litres ---------------------------- |

|

Steam |

--------------------------------- 2.5 to 3

Kgs. ------------------------------- |

|

Fire Wood |

-------------------------------- 0.6 to

0.8 Kgs. ------------------------------ |

|

Coal |

-------------------------------- 0.5 to

0.6 Kgs. ------------------------------ |

|

Gas |

----------------------------------- 0.15 kgs.

--------------------------------- |

|

Space Occupied (mm x mm

x mm) |

9750L x 3400W x 3600H |

14000L x 3500W x 3800H |

14750L x 3800W x 4050H |

|

Weight of Equipment

(without heater) in MT |

6.50 |

8.50 |

12.00 |

|

|

|

* Drying

Capacity varies with moisture content of input tea,

inlet drying / firing temperature & temperature of the

ambient air.

** Installed power ratings given are recommended for

Gas Firing only. In case of Oil Firing, Installed

Power increases by 5 HP and in case of Solid Fuel

(Coal/Wood), it will increase by 10 HP. |

ADVANCED

CONVENTIONAL TEA DRYERS

|

|

Having evolved

over time, the latest ‘Avatar’ of the Conventional MEGAPUT

is a Stainless Steel Tray Dryer with a Made Tea output of

upto 350 kgs./hr under standard CTC wither/drying

conditions.

|

|

INTRODUCTION – THE BASICS OF

CONVENTIONAL DRYING |

|

The

MEGAPUT is a versatile High Moisture evaporative capacity

Machine which has been developed as a result of constant

R&D. This Dryer is equally suitable for Black Tea (CTC &

Orthodox teas) as well as green Tea Drying.

Based on the well proven Tilting Tray theory whereby the

leaf is conveyed on slow-moving perforated trays through

the drying chamber, the MEGAPUT retains all the inherent

advantages of Conventional Drying technology in terms of

preserving the natural bloom, liqueur and taste of tea.

At the same time, a modular design,

innovative technological enhancements such as Stainless

Steel Trays, Roller chain, improved Sprocket design and a

sturdy, insulated steel housing enable the MEGAPUT to

transgress the boundaries and limitations of Conventional

Drying technology. The biggest model, M277, has a 27’ long

and 8’ wide chamber and boasts of an evaporative capacity

of 750 - 800 kgs. of water / hr. The smaller Megaputs are

designed to suit the needs of the individual customer.

The

Megaput Drying Systems are designed to induce about

1350-1500 Air Changes per Hour in the chamber. The

Drying Curve has been optimized by fixing optimum tea

travel ratios between the different tray circuits so as to

optimize drying quality.

|

|

TECHNICAL SPECIFICATIONS |

|

MODEL |

M154 |

M214 |

M156 |

M216 |

M256 |

M277 |

|

Capacity (Made Tea /

hr.)

Single Firing at 72% wither*, 200-210ºF

inlet |

80-100 |

110-130 |

130-150 |

180-210 |

230-250 |

300-350 |

|

Water evaporative capacity (kgs./hr.)

|

180-220 |

250-300 |

300-350 |

450-500 |

550-600 |

750-800 |

|

Installed Power rating (HP)

|

12.75 |

13.75 |

14 |

19 |

26 |

31 |

|

Inlet Drying Temp.

(ºF) |

--------------------------------------------------------------------------------------

200-210

------------------------------------------------------------------------- |

|

Exhaust

Drying Temp.

(ºF) |

--------------------------------------------------------------------------------------

125-130

------------------------------------------------------------------------- |

|

Air Delivery (CFM) |

11,000 |

13,000 |

15,000 |

19,000 |

23,000 |

27,000 |

|

Oil/Gas Burner Size |

2A |

2A |

3A |

3A |

4A |

5A |

|

‘SUPER’ Coal/Wood Heater |

12 |

12 |

14 |

14 |

14 |

16 |

|

Oil Consumption (Direct Fired) |

---------------------- 0.23 – 0.25

litres / kg. of made tea ----------------------- |

------------ 0.20 – 0.22 litres / kg. of

made tea ------------ |

|

Coal Consumption (Indirect Fired) |

----------------------- 0.60 – 0.75

kgs. / kg. of made tea ----------------------- |

-------------- 0.4 – 0.5 kgs. / kg. of

made tea -------------- |

|

Tray Construction |

--------------------------------------------------

Mild Steel, Tin Coated -------------------------------------------------- |

--------- Stainless Steel -------- |

|

* 72% wither indicates

removal of 28 kgs. of water from 100 kgs. of Green Leaves

during withering. In case of Orthodox teas at 55% wither

and 210-215ºF inlet temp., Dryer Made Tea output Capacity

will increase by roughly 30 – 35 %

|

|

'MEGAPUT' FEATURES |

|

VERSATILE

The Megaput comes in varying sizes

and is equally suitable for drying CTC, Orthodox and Green

Tea. The Megaput is available in a series of customizable

Tray designs and throughput times to suit every drying

application.

|

|

ECONOMICAL

With a power consumption of 31 HP, a

coal ratio of 0.4-0.5 and an output of upto 350 kgs./hr.

under standard CTC wither / drying conditions, the M277

Megaput offers unprecedented economy in drying tea. The

smaller MEGAPUTs offer similar economies.

|

|

COLD FEED SYSTEM

The MEGAPUT is equipped with a heavy

duty Cold Feeder Tray system with customizable length. The

slope of the feeder is designed to ensure ZERO slip-back

of tea.

|

|

SPREADER

The Cold Feeder is equipped with a

Revolving height-adjustable Main Spreader Unit which is

inter-linked with an Auxiliary Spreader in the top

circuit.

|

|

VARIABLE

SPEED DRIVE

The Machine is driven through a

time-tested and compact Variable Speed V-Pulley reduction

Gear unit.

|

|

GLASS WOOL INSULATION

The Dryer panels are provided with

double-walled glass wool insulation to prevent heat loss

and increase thermal efficiency. The large inspection

doors, provided for easy supervision, are fitted with

heat-resistant glass to minimize heat loss from the drying

chamber.

|

|

SAFETY DEVICE

All Megaput Dryers are

quipped with a built-in Safety Device System to check tray

jamming and eliminate motor burn-out.

|

|

TRAYS, CHAINS & SPROCKETS

The M277 employs Stainless

Steel Trays with Roller Chain drives to maximize hygienic

drying and minimize wear & tear. The other Megaputs have

heavy duty Tin Coated trays made from 16 gauge sheet with

Roller Chain drives.

|

|

BEARINGS

The

Drying chamber has been provided with standard MSC, MSF

and MST type Ball bearings to enable the shafts to carry

relatively heavy thrust loads.

|

|

FLOOR SCRAPPER

The

Megaput is equipped with a tray-based conveyorised floor

scrapper system to optimize tea recovery and enhance

overall drying quality.

|

|

CENTRIFUGAL FAN

The

Megaput is provided with an Indigenously developed Double

Inlet Hot Air

fan, produced in-house with dynamically balanced rotors.

|